Does AI in Quality Management Reduce Risk, Variability, and Manual Workload?

AI in quality management has reached an inflection point. As regulatory requirements intensify and operational complexity grows, traditional quality processes are struggling to keep pace. Manual inspections, human sampling, and reactive correction models are no longer sufficient for organizations managing distributed teams, global operations, and increasingly stringent compliance demands.

AI-enabled Quality Management Systems (QMS) are emerging as the solution. They transform quality from a periodic checkpoint into a continuous, data-driven function. These platforms automate tasks, detect patterns, predict risks, and eliminate variability at scale. For quality leaders, this shift represents a move from fighting fires to preventing them entirely.

Why Traditional Quality Management Is Breaking Down?

The challenges facing quality teams today are fundamentally different from those of a decade ago. Regulatory bodies are demanding greater transparency and real-time auditability. Operations span multiple sites, shifts, and time zones, making standardization difficult. Meanwhile, quality teams are expected to do more with less—maintaining rigorous oversight while reducing costs.

Traditional QMS platforms weren’t designed for this environment. They rely on manual documentation, periodic sampling, and human interpretation of which introduce delays, inconsistencies, and blind spots. By the time a quality issue surfaces, it may have already impacted customers, compliance status, or operational efficiency.

The result is a system built on reactive correction rather than proactive prevention. Quality teams spend their time documenting problems that have already occurred instead of identifying and addressing risks before they materialize.

What AI in Quality Management Means?

AI in quality management goes beyond simple automation. While traditional systems execute predefined rules, AI-powered QMS platforms analyze patterns, interpret intent, and generate predictive insights. They continuously learn from quality data across interactions, processes, and outcomes—identifying anomalies that would be invisible to human reviewers or rule-based systems.

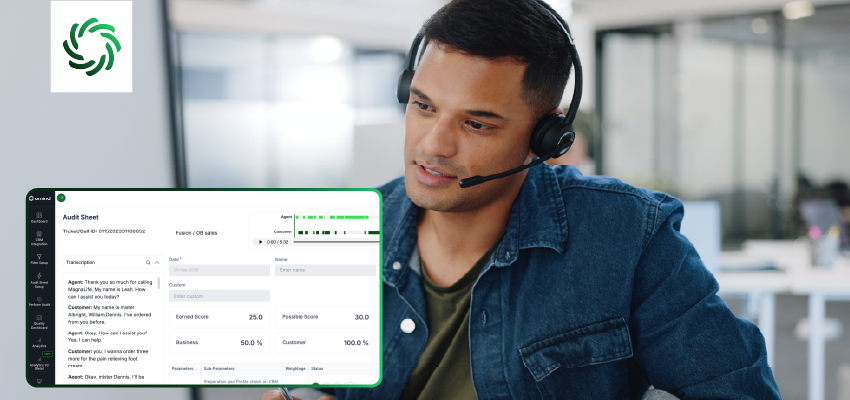

For instance, AI QMS by Omind uses advanced Natural Language Processing (NLP) and Sentiment Analysis to evaluate up to 100% of customer interactions. It spots emotional cues and intent shifts in real time.

This capability transforms quality management into three fundamental ways:

- risk detection becomes predictive rather than reactive,

- assessments achieve full coverage instead of sampling, and

- quality standards become consistently applied across every touchpoint.

Modern AI QMS platforms including Omind’s solution, integrate into existing quality ecosystems, without wholesale system replacement. They connect with LMS, CRM, ERP, and compliance platforms to create a unified view of quality across the organization.

How AI-driven QMS Reduces Operational Risk?

When you talk about risk management, AI becomes the most valuable partner. It offers continuous 24/7 monitoring against your quality standards. This system provides proactive prevention, reducing the pressure and stress on operations.

What AI Does for Your Team:

- Flags the Future: AI catches deviations the moment they occur—not just catching an error but spotting the potential for a larger failure. This gives you the precious time to resolve an issue before it hits a customer or turns into a massive regulatory problem.

- Connects the Dots: Individual errors are easy to handle, but what about the sneaky systemic problems? AI uses powerful pattern recognition to identify trends you’d never see from individual case files. For example: The system notices quality scores consistently dipping every Tuesday afternoon, pointing to a training or shift issue you can now instantly fix.

- Builds a Bulletproof Record: Every quality event is automatically captured, categorized, and linked to policies, essentially creating a transparent, unassailable evidence chain. When regulators come calling, you don’t spend weeks gathering documents; you hand them a crystal-clear narrative.

Eliminating Variability Through Consistent Standards

Human judgment introduces variability into quality assessments. Two reviewers evaluating the same interaction may reach different conclusions based on experience, interpretation, or subjective preferences. While calibration sessions help, they can’t eliminate this variability entirely, across distributed teams.

AI-powered QMS platforms apply standardized criteria uniformly across every evaluation. Scoring models remain consistent whether assessing the first interaction of the day or the thousandth. Quality defects are interpreted using the same logic across all teams, shifts, and geographic locations.

They amplify human expertise, while defining the standards and training models for consistent results. The result is reliable, comparable quality data that supports meaningful performance management and continuous improvement.

Automating Manual Workload Without Reducing Oversight

One of the most immediate benefits of an AI QMS is elimination of repetitive manual tasks. AI quality control automation steps in to handle the administrative load, allowing experts to focus on analysis, coaching, and strategic initiatives.

Key benefits of AI QMS platforms are:

- Documentation is Instant: Tasks that once demanded hours of manual effort—like report generation, event categorization, and evidence gathering—are now completed automatically by the system.

- Faster Resolution: Non-compliances are immediately routed to the right owners with full context. Corrective and Preventive Action (CAPA) workflows are triggered automatically based on preset thresholds, ensuring timely resolution without constant manual monitoring.

AI automation leads to better monitoring. By removing manual bottlenecks, AI enables your quality team to assess more interactions, monitor more processes, and respond to issues faster, all while maintaining rigorous standards and complete audit trails.

The Path Forward for Quality Leaders

AI-driven quality management is rapidly becoming the standard, not an upgrade. Organizations that adopt AI-powered QMS platforms gain competitive advantages in risk management, compliance efficiency, and operational consistency. Those that delay face growing gaps between their quality capabilities and industry expectations.

AI QMS By Omind integrate with existing systems and scale incrementally starting with high-impact use cases and expanding as teams build confidence and capability. The key is to recognize that quality management has fundamentally changed, and the tools must evolve accordingly.

For quality leaders, the question isn’t whether to adopt AI in quality management, it’s how quickly they can implement it to stay ahead of rising complexity, regulatory demands, and competitive pressure.

Are you ready to see how AI transforms quality management? Explore AI QMS by Omind that delivers predictive insights, automated workflows, and enterprise-scale consistency. Let’s schedule a demo.